Key information

Publication type: London Plan Guidance

Publication status: Draft

Contents

1. Introduction

1.1 Purpose of this document

This guidance document explains how to prepare a Circular Economy Statement to accompany planning applications that are referable to the MayorReference:1 as required by the Intend to Publish London Plan (London Plan) Policy SI7, or where boroughs have specified a lower threshold. It can also be used to inform non-referable schemes.

The guidance has been developed and tested with industry and is primarily for anyone involved in, or with an interest in developing Circular Economy Statements, including developers, designers, consultants and local government officials.

1.2 What is the circular economy?

A Circular Economy is defined in London Plan Policy SI7 ‘Reducing waste and supporting the Circular Economy’ as one where materials are retained in use at their highest value for as long as possible and are then reused or recycled, leaving a minimum of residual waste.

The end goal is to retain the value of materials and resources indefinitely, with no residual waste at all. This is possible, requiring transformational change in the way that buildings are designed, built, operated and deconstructed.

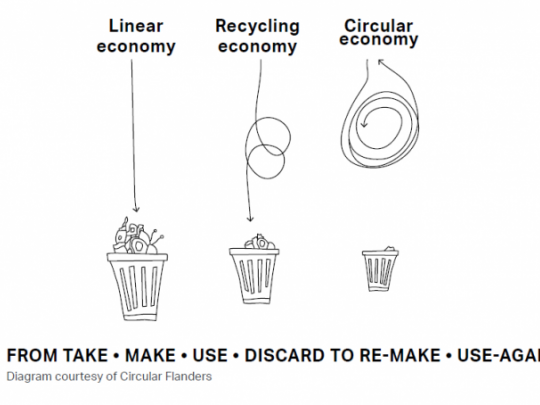

Figure 1.1: Illustration 1

A circular economy stands in contrast to our current linear system, where materials are mined, manufactured, used and thrown away. The ‘Take, Make, Dispose’ model, or ‘linear’ economy, has fuelled rapid growth but is inherently unsustainable in the long term where resources are finite.

Widespread adoption of circular economy principles would dramatically reduce the quantity of new material imported into London and the amount of waste needing to be managed, including that which is exported. Alongside this reduction in imported material and exported waste, smart technologies, infrastructure and logistics can contribute significantly to reduced vehicle movements, air pollution, noise and greenhouse gas emissions. Developers can also benefit from cost savings, for example by purchasing fewer materials and managing less waste.

1.3 Key aims of Circular Economy Statements

Circular Economy Statements are intended to demonstrate how a development, including any public realm and supporting infrastructure, will incorporate Circular Economy measures into all aspects of the design, construction and operation process. This will help to ensure that applicants seeking planning permission for relevant schemes:

- consider strategies to facilitate the transition towards a circular built environment

- report against numerical targets that will facilitate monitoring of waste and recycling

- recognise opportunities to benefit from greater efficiencies that can help to save resources, materials and money.

1.4 Policy context

The Mayor of London wants to see London’s homes, buildings and supporting infrastructure adopt innovative design. London Plan policies D3 ‘Optimising site capacity through a design-led approach’, and SI7 ‘Reducing waste and supporting the Circular Economy’ set out a policy framework that supports the delivery of a circular built environment.

Policy SI7 of the London Plan also requires development proposals that are referable to the Mayor of LondonReference:2 to submit a Circular Economy Statement as part of a planning application.

It states:

Referable applications should promote Circular Economy outcomes and aim to be net zero-waste. A Circular Economy Statement should be submitted, to demonstrate:

- how all materials arising from demolition and remediation works will be re-used and/or recycled

- how the proposal’s design and construction will reduce material demands and enable building materials, components and products to be disassembled and re-used at the end of their useful life

- opportunities for managing as much waste as possible on site

- adequate and easily accessible storage space and collection systems to support recycling and re-use

- how much waste the proposal is expected to generate, and how and where the waste will be managed in accordance with the waste hierarchy

- how performance will be monitored and reported.

In part C of London Plan Policy SI7, London boroughs are encouraged to apply circular economy principles and set their own lower local thresholds for Circular Economy Statements, for example, for ‘major development’Reference:3.

Development proposals that are not required to produce a Circular Economy Statement (non-referable schemes or those that are below local thresholds) are still encouraged to apply the Circular Economy principles and processes set out in this guidance.

2. Applying circular economy concepts to the built environment

2.1 Core principles

Applying circular economy thinking to the built environment is complex, with many overlapping issues and trade-offs to consider. However, there are some core guiding principles that support the circular economy and underpin the structure and content requirements of Circular Economy StatementsReference:4.

At all stages of preparing a Circular Economy Statement, the Waste Hierarchy should be applied to ensure that design measures to avoid or reduce waste are prioritised.

Principle 1. Conserve resources and source sustainably

Reducing the quantities of materials ‘locked away’ in the built environment is critical. The design of buildings, public realm and supporting infrastructure is important because it can influence the types and quantities of materials and other resources that will be used for many decades.

Commitment 1.1 Minimising the quantities of materials used

Designs should consider opportunities to reduce the demand for building materials; for instance, by prioritising refurbishment over demolition. Fundamentally, this requires teams to question the design brief and consider whether it can be met by building less and building more efficiently.

Commitment 1.2 Minimising the quantities of other resources used (fossil fuels, water, land)

Whilst materials are the primary focus of Circular Economy Statements, Circular Economy principles also apply to energy, water, land and ecosystems. For example, building on brown field sites rather than virgin land minimises disruption to the existing landscape, helping to optimise the use of London’s limited resources.

Commitment 1. 3 Specifying and sourcing materials and other resources responsibly and sustainably

This principle covers measures such as specifying the use of reused or recycled materials, installing greywater recycling systems, or participating in reuse schemes. For further information about sustainable sourcing, see Section 6 Glossary of key definitions.

Principle 2 Design to eliminate waste (and for ease of maintenance)

Minimising waste is about tackling waste reduction ‘at source’ and avoiding materials being classified as waste through careful design and specification. This should be considered at the early stages in the context of the whole life-cycle of the development, from strategic planning through to end of life.

Commitment 2.1 Designing for longevity, adaptability or flexibility and reusability or recoverability

The design process should include a realistic assessment of the ability of the development to accommodate change, how frequently it will be reconfigured or remodelled, and how to avoid a premature end of life for all components. This topic is discussed in more detail in Section 3.2.

Careful decision-making in this regard can add value over the life of the development. For instance, commercial buildings may provide generous floor-to-ceiling heights and open grids to ensure that the interior can accommodate a range of tenants. This flexibility could be enhanced by, for instance, using a relocatable, modular internal partition system that would allow for total reconfiguration without the need to purchase additional materials.

Commitment 2.2 Design out construction, demolition, excavation, industrial and municipal waste arising

This principle covers designing out waste by considering opportunities for materials optimisation, reclamation, and reuse. Minimisation of packaging, off cuts, damage and rework should be given special attention through off-site, precision manufacture, just-in-time delivery and secure on-site storage.

When excavating and designing the public realm, topsoil must be given special attention due to its high value and concerns that it is being damaged and wasted at a highly unsustainable rate. Topsoil should never be disposed of to landfill except potentially as a planting medium as part of a site reclamation scheme. Consideration should be given to balancing cut and fill (avoiding any import or export of material) and to techniques that clean and enable reuse of excavation material on site.

Principle 3. Manage waste sustainably and at the highest value

After considering opportunities to minimise the use of resources and design to eliminate waste, developers must demonstrate how they propose to manage any waste that does arise. This includes any waste arising during demolition, excavation and construction , along with municipal waste (resulting from the activities of occupants) and industrial waste, if any.

Any waste arising must be managed as high up the Waste Hierarchy as is practicable.

Management of waste includes the transportation of waste and development proposals should consider ways to consolidate trips, reduce distances travelled and shift the movement of waste to cleaner modesReference:5.

Commitment 3.1 Managing demolition waste

In order to manage demolition waste, applicants must consider undertaking an independent pre-demolition audit, implementing careful demolition strategies, segregating materials and conducting analysis / monitoring of waste flows to maximise reuse and reclamation.

Commitment 3.2 Managing excavation waste

Due to the characteristics of this waste stream, not all of it can easily be reused or recycled, whether onsite, locally or otherwise. Nonetheless, excavation material should be put to the best environmental use that is practicable.

For example, using excavation waste as a resource within the construction of the proposed development (in accordance with the Definition of Waste Code of Practice), seeking opportunities for such material to be used in other local construction projects, or other beneficial uses (for example quarry restoration) should be prioritised above sending waste to landfill.

Commitment 3.3 Managing construction waste

Applicants should aim to incorporate measures for managing construction waste that go above and beyond standard practice where possible.

It is also important to recognise that construction waste arises after the initial construction phase of a development – during the operational phase, due to maintenance, refurbishment, and at the end of life. It may be possible to develop plans for managing this waste, based on repair and replacement forecasts or functional adaptability studies.

Commitment 3.4 Managing municipal waste (and industrial waste, if applicable)

This topic should be reflected in the Operational Waste Management Plan. Adequate, flexible and easily accessible space for segregating and storing waste for collection, recycling and reuse must be provided in line with the London Plan and any relevant local authority guidance.

Both residential and non-residential developments should explore measures such as consolidated, smart logistics and community-led waste minimisation schemes.

2.2 ‘Building in layers’

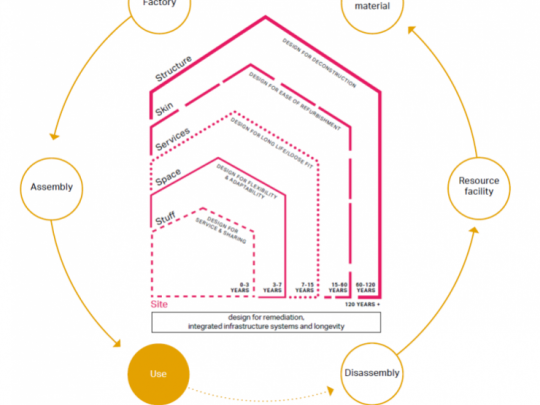

A useful way to understand a building or development is in terms of ‘layers’, where each layer has its own life-cycle that may require a different approach (or different solutions) to be adoptedReference:6. This concept is illustrated in Illustration 2 below.

Figure 2.1: Illustration 2

For example, the structure of a building will typically be designed to last for 100 years or more whilst features like the façade may be replaced two or three times over the life of a building. Bathrooms, kitchens, flooring, furniture and furnishings will typically be replaced much more often.

Taking a design approach that recognises these distinctions, the structure and façade of a development may be built to be long lasting and adaptable, whilst individual components like the services, interior space and furnishings are designed in a way that supports reuse or recycling.

The layers that are commonly referred to across industry are defined below, with reference to the RICS New Rules of Measurement (2012) where relevant. These form the basis of several of the Circular Economy Statement reporting forms, which prompt applicants to develop circular economy strategies for each building ‘layer’ over the life-cycle of a development.

3. The stages of developing a Circular Economy Statement

3.1 Submission of Circular Economy Statements at different stages

The production of a Circular Economy Statement involves three steps that take place at different stages of the development process:

- Step 1: Pre-application (or submission of outline planning application) stage à submit a Draft Circular Economy Statement which focuses on the strategic approach to the circular economy

- Step 2: Full application stage (or application for reserved matters) à submit a Detailed Circular Economy Statement, where the emphasis then shifts to how the circular economy will be addressed through detailed design.

- Step 3: Post-planning/completion updates (specific to each project) à submit an update to the Detailed Circular Economy Statement that details progress against the targets and commitments defined in Steps 1 and 2. The need for updates will be determined during the planning application process but these should typically be provided from the construction phase onwards.

For masterplan-led developments where limited design information is available, the Circular Economy Statement should focus on the work carried out to assess opportunities for re-use of any materials, buildings or resources on site. It should also describe any strategic ways that the masterplan will promote circular economy measures.

As shown in the table below, the Circular Economy Statement should include input from the developer and their consultants including the design team and contractor(s), suppliers, facility managers, waste managers and end users (where possible). Compiling the requisite information will require at least one meeting or workshop during the outline planning application stages, and another during the full planning application stage.

3.2 Starting out - defining a strategic approach to the circular economy

In order to implement circular economy principles most effectively, it is helpful to explore high-level strategic opportunities as early in the development process as possible. This should feed into the development of a Draft Circular Economy Statement.

Choosing the most appropriate circular economy strategy will depend on context, the nature of the development, owner and occupier needs. The strategy should be determined during concept design and should form part of the development brief. Feasibility studies, surveys, audits and other investigations may be required to understand what options are appropriate. The approach may evolve as the design evolves, or in response to wider considerations. Applicants should therefore be prepared to review and change approaches as appropriate.

In many cases, a different approach should be adopted for different parts or areas of the development, such as:

- Existing buildings/components versus new buildings/component

- Long lifespan buildings/components versus short lifespan buildings/components

Some of the different strategic approaches that can be adopted are listed below. These are not mutually exclusive but can provide an overarching framework for teams to define the strategic approach to a given project (or part of project).

To identify the appropriate strategic approach, applicant teams are encouraged to use the ‘Decision Tree’ on the following page. It prompts designers and developers to consider, in the early stages, opportunities for maximising the residual value of any buildings, materials or elements on site, before considering strategies for adding value over the lifetime of the development.

As explained in more detail in Section 4, applicants must describe and justify their strategic approach in the Circular Economy Statement within Table 1, using the template provided in Appendix A.

4. Structure and contents of a Circular Economy Statement

4.1 Structure of a Circular Economy Statement

The table below shows the key elements of a Circular Economy Statement. It can be used as a compliance checklist or indicative Table of Contents. Further details on each section are provided in subsequent pages.

4.2 Integration of Circular Economy Statements with other supporting documents

Where other relevant documents – such as Waste Management Plans, Design and Access Statements, Energy Statements, and other environmental/sustainability statements - are bring submitted as part of a planning application, it may be appropriate to cross-reference relevant parts of these documents (rather than repeat information) in the Circular Economy Statement, provided that cross-referencing is clear and the documents referred to contain sufficient information to allow a full assessment of the application.

In particular, there is likely to be some overlap between the strategies identified in the Circular Economy Statement, and the actions prescribed within the Site Waste Management Plans and Operational Waste Management Plans or similar.

4.3 How are Circular Economy Statements assessed?

Circular Economy Statements must adhere to minimum content requirements in order to be considered ‘compliant’ with this guidance for meeting London Plan policy. Applicants are encouraged to go beyond compliance by adopting more ambitious strategies or targets (see the relevant sections on ‘pioneering statements’).

At pre-application/outline and detailed planning application stages, the Circular Economy Statements will be checked for:

- Completeness – Does the Statement contain the core information described in Section 4? Has the applicant demonstrated that circular economy principles have informed the proposals?

- Technical validity – Are the commitments relevant to the project? Has the applicant demonstrated that there is a reasonable process in place that will help them achieve and monitor their stated targets?

- Level of ambition – Does the Statement include clear commitments to circular economy measures that go above and beyond standard practice?

Projects seeking to go beyond the ‘compliant’ standard to demonstrate a ‘pioneering’ level of commitment to the circular economy can do so by:

- Showing depth – exceeding the minimum policy requirements, or otherwise going above and beyond standard practice; and/or

- Showing breadth – setting additional targets (for example, see ‘Optional’ metrics in Section 4.4), demonstrating that a broad range of measures have been investigated.

The GLA recognises that, in some cases, an achievement may not be adequately captured by numerical metrics. Examples could include retaining and refurbishing a building that might otherwise be demolished, working with a supplier to develop a leasing scheme for building components, or using an innovative product such as a compostable plasterboard alternative.

In such cases the applicant should highlight the achievement within the ‘narrative’ portion of the Circular Economy Statement (see Section 4.4), explaining:

- how it reflects the objectives of London Plan policies relating to the circular economy

- any other benefits for occupants, neighbourhoods, local authorities, etc. These may be qualitative or quantitative but will need to be backed up by evidence at application stage (for example reports, calculations or specification documents) and post-completion (for example surveys or monitoring results) as relevant.

Draft London Plan Policy SI7 B(6) states that referable applications need to demonstrate how performance of the Circular Economy Statement will be monitored and reported. This must include:

- what actually happened

- how this is different from what was planned

- why it differed and what the key learnings were

This will help to promote good practice. This should be appropriately secured at the planning stage. Section 4.4 ‘Reporting Outcomes’ sets out how this should be done post-completion.

4.4 Contents of a Circular Economy Statement

Title Page

The title page of a Circular Economy Statement should contain:

- The name of the development and planning application reference

- If it is a Draft or Detailed Circular Economy Statement or a Post-planning/completion Update

- Authors of the Circular Economy Statement (organisation)

Executive Summary

The title page should be followed by a non-technical summary of the circular economy approach and commitments as they stand at the stage of production. At the pre-application stage (or for outline planning applications) the summary will be less extensive than at the full application stage.

The executive summary should include:

- Identities of all organisations engaged in development, design and delivery

- A brief description of the development and any context

- A description of strategic approach(es) for each part of the proposed development for example existing buildings, new buildings, different areas or phases as appropriate (see Section 3.2)

- A summary of the specific commitments being made, focusing (where possible) on commitments that go above and beyond standard practice. For example, crushing bricks for reuse in pile cappings is standard practice; cleaning and reusing whole bricks onsite retains the value of the material, avoids the need for new bricks and is therefore more in line with circular economy principles.

- A summary of the overall implementation approach (‘who, what, when and how?’)

The aim should be to summarise this information on one to three pages, including any images, diagrams or tables.

Description of the Development

The description of the development should be brief, relevant and include buildings, public realm and supporting infrastructure. It should include:

- a short description of any existing development and/or resources found on the site

- the proposed floor area (GFA, GIA and NIA) for each use

- the number of residential units (e.g. 450 flats and 70 houses)

- the approximate size/capacity of any new public realm or supporting infrastructure

- any other important information or context needed to understand the approach taken, for example, site constraints, unique features, requirements of the brief, etc.

The description of the development should outline the number of different areas, buildings or phases addressed by the statement and this should correspond with the number of versions of Table 2 found later in the Statement.

Method Statement

A method statement should provide a summary of the process followed up to the point of submission and how the team approached the application of circular economy principles and the production of the Statement. This can include a summary of the meetings and workshops held, including key points, attendance, outputs and actions. For a Draft Circular Economy Statement, the method statement will contain less detail but should provide a summary of steps taken thus far and note any important further steps that are planned (for example, additional workshops at the detailed design stage).

The applicant should be able to demonstrate how this process has influenced the project brief, and any other aspects of the design, procurement and construction process. Supporting evidence of the approach taken and how this has evolved (e.g. meetings and outcomes) can be provided in the appendices.

Circular Economy Aspirations

In this section, applicants have the chance to explain how they interpret the circular economy, their view on how it improves sustainable development outcomes and their priorities to accelerate the transition, including any organisational circular economy strategy or targets that have been set.

Applicants should explain how the proposed development links with these wider circular economy aspirations, and any unique goals for this project.

Relevant experience and past developments should be mentioned, along with any notable circular economy outcomes achieved to date.

Strategic Approach(es) – Summarised in Table 1 (Appendix A)

Section 3.2 provides guidance on deciding on a strategic approach to the circular economy. Once the strategic approach has been agreed, the rationale should be summarised in Table 1. A template of Table 1 is provided in Appendix A.

At least one meeting/workshop should take place at an early stage for the developer and design team to consider the brief and discuss the overarching circular economy strategy for the project. Where possible, input from planners and/or contractors should also be sought.

Completing Table 1 requires those involved to:

- agree the strategic approach(es) to the circular economy

- explain the approach with reference to London Plan policy requirements and targets

- identify supporting information that will be required in order to set specific targets and prove that they are achievable – for example audits, surveys, investigations and studies

Additional meetings/workshops may be necessary to develop the approach before finalising which measures will be adopted. Some detailed feasibility work may be required to translate opportunities into specific implementable measures.

Draft and Detailed Circular Economy Statements must provide a completed Table 1 with additional rows for different phases, buildings or areas, if and where a different strategic approach is proposed.

Provide additional text as needed to explain the content in Table 1, if not covered in the introductory sections.

Draft Circular Economy Statements only: Preliminary Targets/Commitments

Design teams, developers and any other relevant stakeholders (for example contractors, building operations managers) teams will need to reach a preliminary agreement regarding which targets and commitments they will report against at the full application stage, and list these within the Draft Circular Economy Statement.

The Draft Circular Economy Statement should identify any surveys, audits, studies or analysis required to provide a strong evidence base for decisions to be taken during the next step of the process/RIBA Stages 2 to 5. This will help to ensure that the goals discussed at an early stage are integrated into the design process and documented appropriately.

This section of the Draft Circular Economy Statement will be replaced with specific commitments (see below) in the Detailed Circular Economy Statement.

Key Circular Economy Commitments - Summarised in Table 2 (Appendix B)

In preparation for a detailed planning application, the focus should shift from strategy to action and a deeper understanding of feasibility and the technical challenge of the development, capitalising on the opportunities related to the policy requirements and targets.

Table 2 prompts applicants to consider how they can apply the nine circular economy principles (see Section 2.1) to each building ‘layer’ (see Section 2.2). Opportunities should consider all life-cycle stages of each layer. A template for Table 2 is provided is provided in Appendix B.

Table 2 is only required for Detailed Circular Economy Statements; however, it can be submitted in draft form at the pre-application stage (or for outline planning applications). It is intended as both a procedural tool to help guide workshops and discussions and as a practical tool to highlight key circular economy commitments within a full planning application.

Additional copies of Table 2 should be completed for different phases, buildings or areas, if and where a different strategic approach is proposed and/or different targets apply.

The contents of Table 2 should evolve, be refined and updated as the designs progress. Note that revision of Table 1 may prove necessary based on Table 2 and the developer should be engaged in these decisions.

The commitments listed in Table 2 as part of the Detailed Circular Economy Statement submission should only be those that hold the greatest opportunities, representing the strongest commitments that go above and beyond standard practice where possible.

Reporting Forms – Bill of Materials

Applicants must demonstrate that they have considered opportunities to conserve resources by applying lean design principles and to source materials sustainably. This information is captured in the ‘Bill of Materials’ form (for which a template is provided in Appendix C).

‘Compliant’ Detailed Circular Economy Statements must include a completed Bill of Materials which estimates the quantity of materials used in each ‘layer’ of the building (kg), the material intensity (kg/m2 GIA) and set targets for the minimum amount of recycled content to be used (% by value).

The purpose of reporting material intensity is twofold: first, to gather evidence about the material intensity of different structural systems and development types; and second, to ensure that material optimisation is considered as part of the design process.

Applicants should review different structural options and determine whether the least material intensive construction has been selected. If it has not been selected, assess whether the rationale for not selecting it aligns with the Circular Economy strategic approach (e.g. refurbishment of an existing building, design for adaptability, disassembly, or similar).

Applicants should identify opportunities for use of reused or recycled materials and set individual targets of at least 20 per cent by value of materials. This should be evidenced: for instance, if reporting on the amount of reused content, the applicant should provide information about where the material will be sourced from and whether any repairs or additional work will be needed to make it useable.

Note that many production activities that are currently referred to as ‘recycling’ are in fact ‘downcycling’. Examples include solid timber being turned into chipboard, or bricks being crushed into aggregate. In a circular economy, the aim should always be to ensure that the material is brought back to a comparable or higher level of quality and value.

Recognising that opportunities will be unique to each development, applicants can either report against targets for different building layers (for example, structure, shell/skin and space) or for different materials (for example, metals, plastic, timber). If reporting by material, calculations should focus on those with the highest value and aim to address at least 80% of the material used (i.e. 80% by value). If reporting by building layer, applicants should focus on the ‘structure’, ‘shell/skin’ and ‘space’ as a minimum.

Applicants must provide the following evidence in appendices:

- building weight calculations (load take-down) to be used in calculating material intensity

- reused or recycled content calculations, including supporting details such as Environmental Product Declarations, specification documents, etc.

Pioneering statements may include additional columns or rows where additional commitments are being made (examples of this are provided in Appendix C shaded in grey). For instance, a building containing elements that can be 100% reused at end of life might include an additional column for ‘Estimated reusable materials (kg/m2)’ or similar. Applicants should provide appropriate evidence for any additional commitments made.

Post-planning, applicants should provide an updated Bill of Materials with actual figures, indicating where these differ from those provided at planning stage where known, with supporting calculations. The following table provides further information relating to the Bill of Materials and describes the calculations required to complete it.

Reporting Forms – Recycling and Waste Reporting Form

The Recycling and Waste Reporting Form (see Appendix E for a template form) is a template for reporting the total amount of waste/material generated during excavation, demolition, construction and operation. At the planning stage, these figures will be estimates; after construction, applicants will be expected to provide an updated form with actual monitored figures.

In order to be ‘compliant’ with this guidance, Detailed Circular Economy Statements must include a Recycling and Waste Reporting Form with clearly defined activities and targets relating to the following London Plan policy targetsReference:7:

- 95% reuse/recycling/recovery of construction and demolition waste

- 95% beneficial use of excavation wasteReference:8

- 65% recycling of municipal waste by 2030

Providing metrics relating to excavation, demolition, construction, municipal waste and industrial waste (where relevant) help to ensure that the proposals acknowledge opportunities to design out waste over the course of the development’s life span and effectively meet specific London Plan targets for managing waste and material streams.

As illustrated in Illustration 4 below, applicants should provide an estimate of the total amount of waste or excavation material arising. Then, they should indicate how much will be reused or recycled onsite, how much will be reused or recycled offsite, and the residual waste that will be sent to landfill. If the proposal will include a mixture of existing/refurbished and new buildings, estimates should be provided for these elements separately and in total.

After on-site opportunities have been exhausted, applications should refer to the London Waste Map to consider opportunities for using local sites to manage materials and waste where practical. This will help keep the value of materials and waste circulating in London, and support achieving the Mayor’s 100 per cent net waste self-sufficiency target by 2026Reference:9. Reporting on the amount of waste generated and managed will help applications to monitor performance and help the GLA monitor progress towards its circular economy and waste policies and targets.

With regards to the material that is recycled either on or off site, applicants should indicate in the text how the material will be used, distinguishing between uses that maintain or improve the value of a material, and uses that reduce the value of a material (i.e. ‘downcycling’).

For each metric, applicants should state the methodology or tools used to supply the estimate. They should also cross-reference the relevant section of the Circular Economy Statement describing the process for optimising use of materials, sustainable sourcing and monitoring/reporting. Estimates should align with the Site Waste/Resource Management Plan(s) and Operational Waste Management Plan.

In order to complete the Recycling and Waste Reporting Form, applicants should provide the following evidence in appendices:

- cut and fill calculations

- reused or recycled content calculations, including supporting details such as Environmental Product Declarations, specification documents, etc.

- relevant extracts from the Site Waste/Resource Management Plan

- relevant extracts from the Municipal/Operational Waste Management Plan

In addition, when it is intended to send waste to landfill applicants must provide written confirmation that the receiving landfill has the capacity to deal with the waste over the lifetime of the development, along with a notification of the likely destination of all waste streams (beyond the Materials Recycling Facility) where knownReference:10. Where possible, confirmation should be provided for all waste handling facilities, in or outside LondonReference:11.This should be supported by the calculations/estimates of waste arising and these figures must align with the Recycling and Waste Metrics form. During construction, applicants should record the source of all waste arising and monitor using a waste management tool (such as SmartWaste).

Post-completion, applicants should provide an updated Waste and Recycling Reporting Form with actual figures, indicating where these differ from those provided at planning stage where known. They should also provide confirmation of the actual destination and amounts of waste and excavated material managed (for example, figures from recycling facilities by recycling percentage), and that the ultimate receiver of material (for example another site) had capacity.

The following table provides further information relating to the Recycling and Waste Reporting Form and describes the calculations required to complete it.

Optional Reporting Forms – Pioneering statements only

Applicants wishing to demonstrate ‘pioneering’ Circular Economy Statement status may wish to provide an Enhanced Bill of Materials (see Appendix E for an example). An Enhanced Bill of Materials would use the same template as the normal Bill of Materials, but design teams would add rows or columns to set additional targets for specific parts of the building(s).

For example, an Enhanced Bill of Materials would be suitable for a project where the developer was committed to sourcing all interior furniture and fittings from the secondary materials market.

Alternatively, the applicant may wish to provide a ‘Future’ Bill of Materials (see Appendix F for further details). This would involve estimating the amount of construction and demolition waste generated over the lifetime of the building(s) (for example due to repairs, refurbishment or decommissioning) and demonstrate how this waste has been minimised. Similarly, applicants could provide additional information within the Recycling and Waste Reporting Form.

A Future Bill of Materials or Recycling and Waste Reporting Form would be suitable for a building that is designed to be 100% disassembled and reused at end of life.

Applicants should provide calculations, studies or other evidence in the appendices as necessary to support any additional commitments or targets made. The following table provides further information relating to the optional reporting forms and describes the calculations that could be used to complete them. Applicants are free to adapt these as desired in order to showcase pioneering circular economy measures.

Circular Economy Narrative

This section of the Statement will provide a more detailed description of how the targets presented in Tables 1 and 2, the Bill of Materials and the Recycling and Waste Reporting Form will be achieved. For some projects, particularly those where key commitments are not adequately captured in terms of numerical metrics, this section provides an opportunity to elaborate on the proposals and their benefits.

This part of the Circular Economy Statement should include clear, strong commitments and targets. It should be structured to provide a response to each of the core principles described in Section 2), with the aim of limiting subsections to one page where possible.

Each subsection should contain the following:

- a short summary of the proposed approach

- itemised metric(s) and target(s)

- commitments and measures that will be adopted – these should be short, written in accessible language, along with key information about how each measure will be implemented

- anticipated challenges and counter-actions

Summarise and cross-reference other planning documents, calculations and reports as relevant. Other information should be supplied in the appendices.

Plans for Implementation

Explain how short- and medium-term targets or commitments will be implemented, monitored and reported. Consider the questions, ‘who, what, when, and how?’. The aim is to demonstrate that the applicant has identified specific, achievable targets and committed to their delivery.

Actual performance against these targets should be submitted at practical completion (see ‘Post-completion Report’ section below).

For longer-term targets, applicants should provide a description of the method(s) that will be used to ensure they are met, and a programme of key milestones (e.g. completion, monitoring intervals, and so on).

End-of-life strategy

Applicants should describe the strategy for how the proposal’s design and construction will reduce material demands and enable building materials, components and products to be disassembled and reused at the end of their useful life.

Building information should be stored (for example, by using Building Information Modelling) to facilitate end of life strategy, disassembly, future reuse, waste avoidance and waste reduction.

Applicants should describe the content and format of the strategy and how this will be communicated to future building users. They should also outline key challenges that may prevent the strategy from being implemented, and how these have been addressed to the greatest extent that is feasible at this stage.

Reporting Outcomes – Post-completion Report

This update to a Circular Economy Statement should be filled out post-planning/completion and sets out the targets and actual outcomes achieved. To some extent, the structure and content will therefore be specific to each development.

As a minimum, applicants must produce a Post-completion Report setting out the predicted and actual performance against all numerical targets, and provide updated versions of Tables 1 and 2, the Recycling and Waste Reporting Form and Bill of Materials.

Applicants should clearly indicate where any variation has occurred and why (i.e. if a target has been exceeded or has not been met).

They should also provide evidence and supporting documentation as appendices. These could include, for instance:

- evidence of audits

- written agreements or correspondence

- drawings or photos

- specifications

- performance and test certificates

Lessons learned

In order to inform and improve the Circular Economy Statement process, structure and contents, applicants should describe the important lessons learned and summarise these in their Post-completion Report.

These should be captured at each stage of design and construction. Assigning an individual or individuals to capture lessons is crucial to ensure that these are fully understood and communicated to the wider team.

Lessons should be presented in a way that will help future development understand how best to achieve the London Plan circular economy policy objectives (see Section 1.4). This information will also be used to inform future London Plan policy and guidance.

‘Pioneering’ Circular Economy Statements should look beyond the technical challenges and analyse structural and other issues that have to be addressed to achieve significant circular economy goals. Information captured should be validated and shared across the industry wherever possible.

Appendices

The appendices should provide an evidence base for the commitments, targets and metrics contained within the Circular Economy Statement, and should include the detailed technical studies or calculations that has underpinned the content in the main body of the Statement. The following items should therefore typically be provided to support the applicant’s Circular Economy Statement:

- circular economy workshop/meeting outcomes (where relevant and useful)

- independent pre-refurbishment/pre-demolition audit

- scenario modelling demonstrating adaptability

- lean design options appraisal

- building weight calculation (load take-down)

- reused or recycled content calculations

- cut and fill calculations

- references to the relevant extracts from the Site Waste/Resource Management Plan

- references to the relevant extracts from the Municipal/Operational Waste Management Plan

- written confirmation that receiving landfill has the capacity to deal with waste arising over the lifetime of the development

Other supporting documents will depend on the specific commitments made for a given project, but might include:

- design for deconstruction/disassembly study

- Environmental Product Declarations (as evidence of recycled content, healthy materials, renewable energy used in the manufacturing process, etc.)

- in-use replacement and repair estimates (if providing a Future Bill of Materials)

- Material Circularity Index value and supporting information

- Building as Material Banks (BAMB) assessment

The above lists are not exhaustive; the applicant should use their judgement as to what supporting information will be necessary to undertake an informed assessment of the Circular Economy Statement.

5. Additional resources

Further guidance on how to embed Circular Economy thinking into construction projects with examples include:

- Mayor of London, Circular Economy Primer: Designing for a Circular Economy

- LWARB, London’s Circular Economy Route Map (2015)

- UKGBC Guidance

- Designing out waste (WRAP)

- Building as Materials Banks project papers (BAMB)Reference:14

- Building Revolutions, RIBA Publishing

- Circularity Indicator ProjectReference:15

- Cradle to Cradle Building CharterReference:16

- Designing Buildings Wiki

- Ellen MacArthur FoundationReference:17

- Green Construction Board’s Top TipsReference:18

- Sustainability assessment methods i.e. BREEAM, SKA, HQM, WELL, Fitwell

- The Re-Use Atlas: A Designer’s Guide Towards a Circular Economy, RIBA Publishing

- UK Green Building CouncilReference:19

- LWARB toolkits and guidance for flatted propertiesReference:20

- Pre-redevelopment audits, Code of Practice, BRE, July 2017

6. Glossary of key definitions

Waste management definitions

Appendix A – Table 1: strategic approach

Appendix B – completing Table 2

Teams can use Table 2 to facilitate Circular Economy workshop(s) to ensure that all opportunities have been considered for each layer of the building. Prior to submission, teams should review the table to check for coherence and ensure that all commitments are accompanied by a specific delivery strategy.

Further details are provided below.

Below are sample prompts that can be used during a Circular Economy workshop to help fill in Table 2. Counter-actions should be specific to each project or organisation.

A template is provided on the following page.

Appendix C – Bill of Materials template

Appendix D – Recycling and Waste Reporting Form

Appendix E – Examples of optional metrics (pioneering statements only)

The following templates can be used or adapted by ‘pioneering’ developments to demonstrate that consideration has been given to minimising and managing the waste arising during the operational phase of the building (e.g. repairs, replacement, maintenance) and/or at end of life.

‘Future Bill of Materials’

‘Enhanced’ Waste Reporting

References

- Reference:1As defined in the Town and Country Planning (Mayor of London) Order 2008. See /programmes-strategies/planning/planning-applications-and-decisions/what-powers-does-mayor-have-planning-applications for more details.

- Reference:2As defined in the Town and Country Planning (Mayor of London) Order 2008. See /programmes-strategies/planning/planning-applications-and-decisions/what-powers-does-mayor-have-planning-applications for more details.

- Reference:3As defined in the Town and Country Planning (Development Management Procedure) (England) Order 2015.

- Reference:4The principles are consistent with implementing the EU waste hierarchy and with the circular economy systems thinking approach developed by the Ellen MacArthur Foundation (EMF).

- Reference:5See London Plan policies T7 Deliveries, servicing and construction, SI 15 Water transport and the Mayor’s Transport Strategy for further detail

- Reference:6See Frank Duffy’s ‘Shearing Layers’ concept described in ‘How Buildings Learn’ by S. Brand (1994).

- Reference:7London Plan Policy SI7 Reducing waste and supporting the circular economy

- Reference:8The stricter definition of ‘landfill’ post-Methley Quarry judgement and recent changes to the regulatory regime for excavated materials means that some permitted sites that are defined as ‘landfill’ by the Environment Agency can be included in the definition of ‘beneficial use’ by the GLA. The developer should explain in detail why a proposed site may be regarded as ‘beneficial’ in these circumstances. Every effort should then be made to use the material in other innovative ways, and to find markets for the products produced from it, in accordance with the waste hierarchy, without causing harmful impacts on the natural environment.

- Reference:9London Plan Policy SI8 Waste capacity and net waste self-sufficiency

- Reference:10London Plan Policy SI7 Reducing waste and supporting the circular economy, paragraph 9.7.5

- Reference:11The UK Department for Environment, Food & Rural Affairs Waste Duty of Care Code of Practice (2018) states: ‘You have a responsibility to take all reasonable steps to ensure that when you transfer waste to another waste holder that the waste is managed correctly throughout its complete journey to disposal or recovery.’

- Reference:12London Plan Policy SI7 Reducing waste and supporting the circular economy, part A6.

- Reference:13Developments that fall within Category 1B, Part 1 of The Town and Country Planning (Mayor of London) Order 2008.

- Reference:14www.bamb2020.eu/library/papers/

- Reference:15https://www.ellenmacarthurfoundation.org/resources/apply/circularity-in…

- Reference:16www.c2c-centre.com/library-item/cradle-cradle%C2%AE-building-charter

- Reference:17www.ellenmacarthurfoundation.org/assets/downloads/Built-Env-Co.Project…

- Reference:18www.cetoptips.com

- Reference:19www.ukgbc.org/resource-use/

- Reference:20https://www.lwarb.gov.uk/what-we-do/resource-london/successes-to-date/e… https://resourcelondon.org/resources/toolkits/ Updated flats guidance (expected in 2020) should be applied.

- Reference:21https://www.bsigroup.com/en-GB/bes-6001-responsible-sourcing-of-construction-products/

- Reference:22EU Directive 2018/851

- Reference:23EU Directive 2018/851

- Reference:24EU Directive 2018/851